Precision Investment Casting & Machining for the Automotive Industry

High-performance, certified components engineered for reliability under extreme conditions.

- Home

- »

- Automotive Investment Casting

Automotive Investment Casting & Precision Machining

Components for the automotive industry require exceptional durability, high performance, and precise dimensional accuracy to withstand extreme operating conditions.

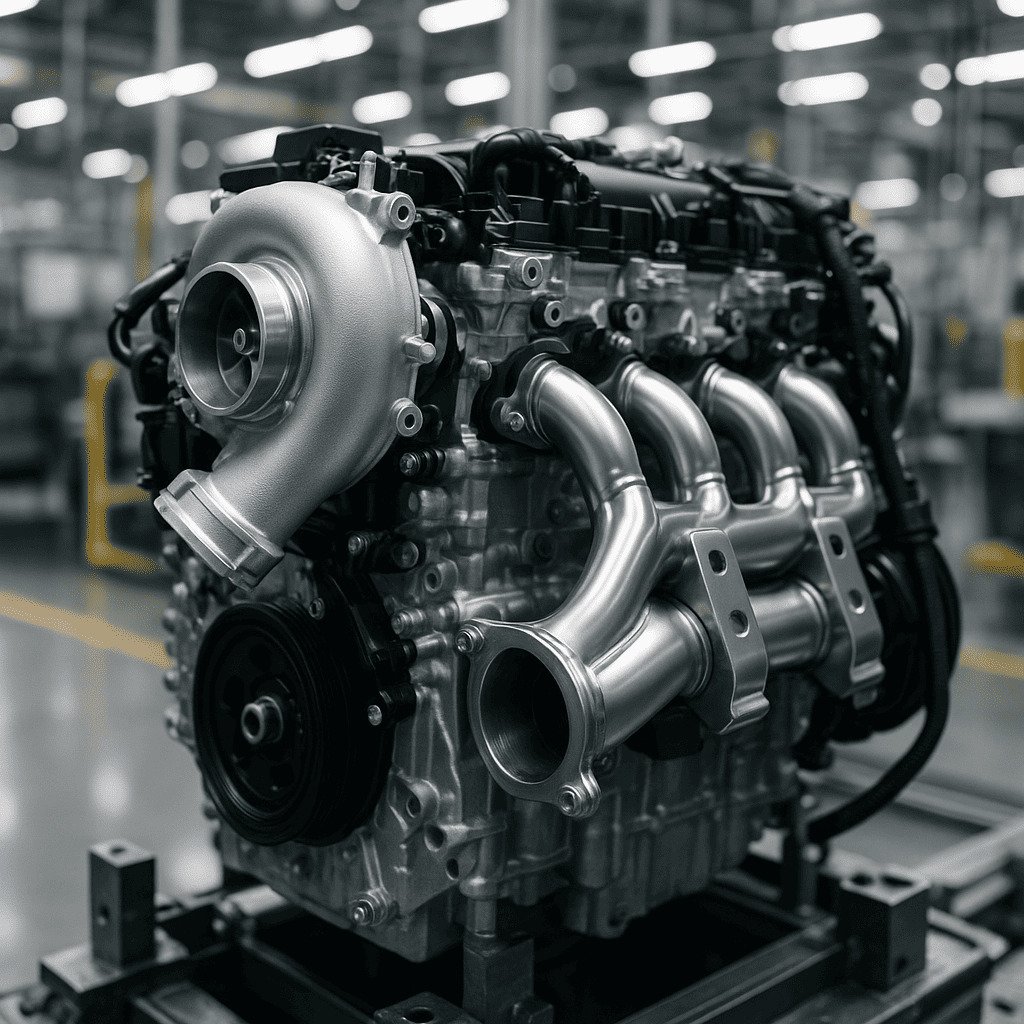

At Vastcast, we manufacture and supply investment castings and precision-machined parts for a wide range of automotive applications, including engine systems, chassis structures, heat management solutions, and drivetrain components.

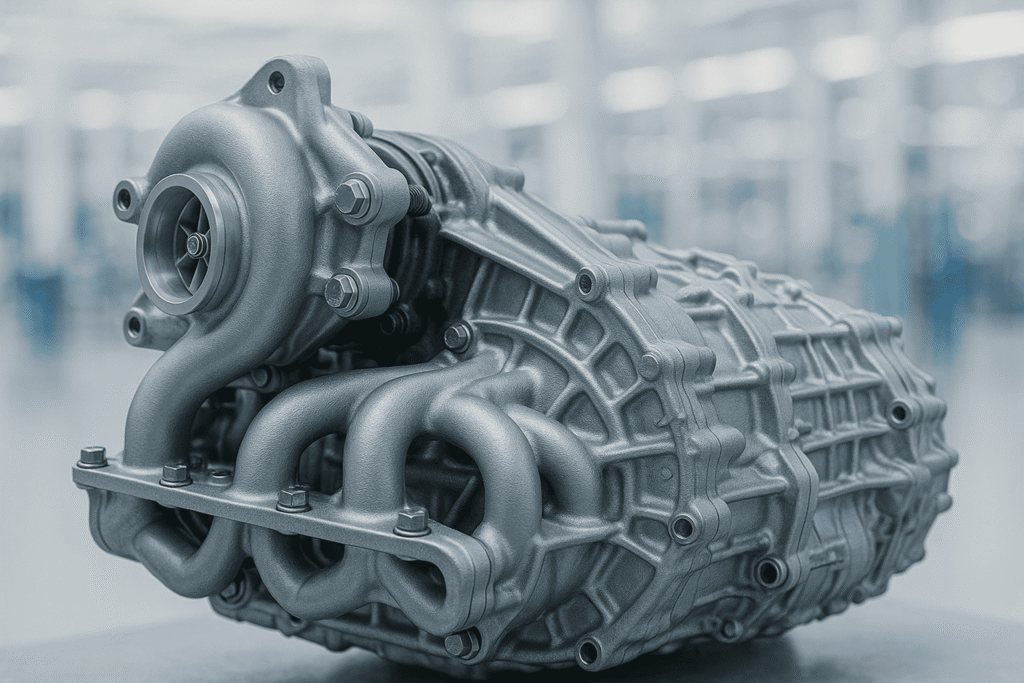

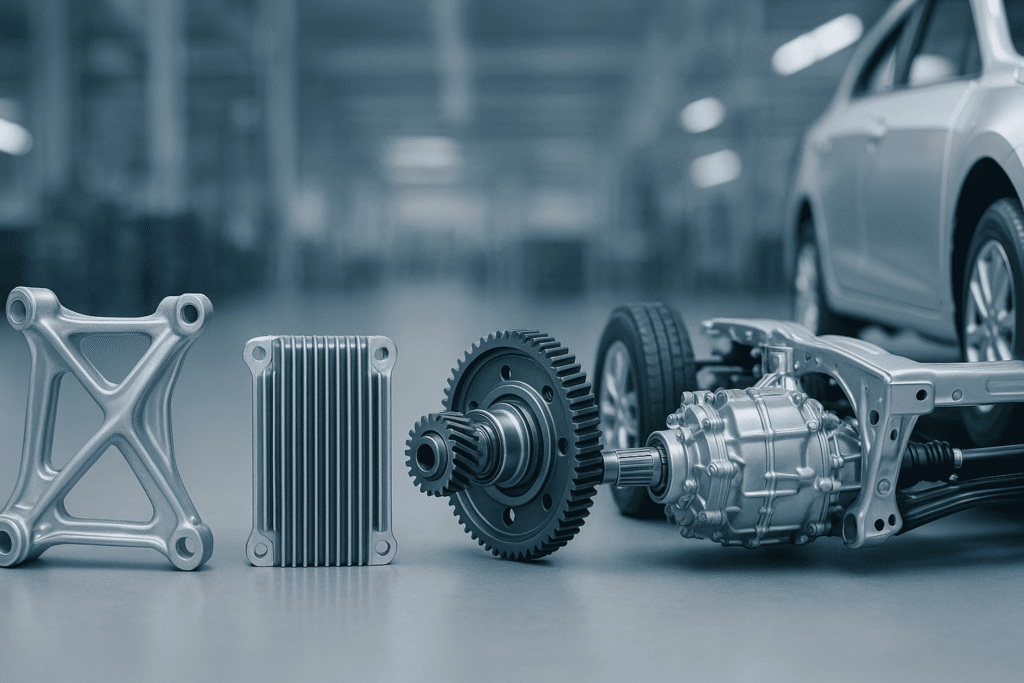

These parts are widely used in turbochargers, manifolds, suspension systems, transmission housings, and other critical automotive assemblies.

We have established long-term partnerships with automotive manufacturers and Tier 1 suppliers. With our one-stop production capability, we deliver high-quality castings and precision components with fast turnaround times.

We process materials such as stainless steel, aluminum alloys, heat-resistant steels, and titanium alloys. Sizes range from small precision parts to large structural castings, with weights from a few grams to over 80 kg.

Automotive components demand superior strength, heat resistance, wear resistance, and lightweight performance. For example, turbocharger housings and exhaust manifolds are cast with high-temperature alloys, while structural parts leverage aluminum alloys to reduce vehicle weight and improve fuel efficiency.

Materials & Processes

Reliable medical-grade components, tailored with precision.

Materials

🟢 Stainless Steel (316L, 17-4PH)

Corrosion-resistant, suitable for engine and exhaust components.

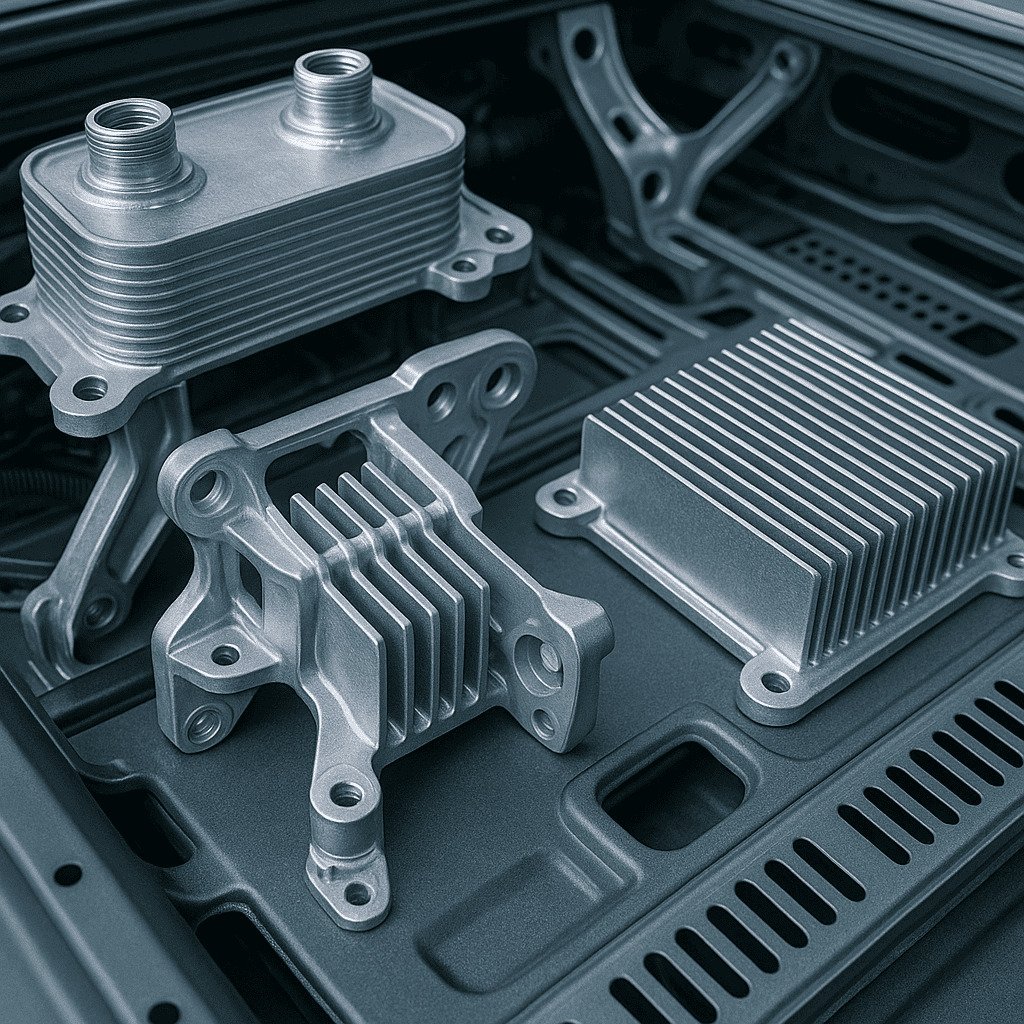

🔵 Aluminum Alloys

Lightweight yet strong—ideal for heat sinks and structural parts.

🟠 High-Temperature & Specialty Alloys

Built to endure automotive heat, pressure, and wear.

Processes

⚙️ Automotive Investment Casting

For robust & thin-walled components with complex geometries.

🔧 CNC Precision Machining

Tight tolerances ensure consistent fit and function.

✨ Surface Treatments

Polishing, anodizing, and coatings for durability and aesthetic finish.

Applications in the Automotive Industry

Delivering Precision Solutions Across Automotive Applications

Engine Components

Turbo housings, manifold brackets, and heat-resistant parts.

Chassis & Structural Parts

Lightweight castings with structural integrity.

Heat Dissipation Solutions

Engineered heat sinks, cooling brackets, and fins.

Transmission & DrivetrainComponents

Reliable, wear-resistant parts for long-term use.

Optional Subtitle

Why Choose Us?

If you are looking for the right automotive investment casting manufacturer in China, we are your best choice!

Expert Engineering Team

Seasoned professionals skilled in automotive casting and machining excellence.

Assured Quality

ISO 9001:2015, ISO 14001:2015, OHSAS 18001:2007—every batch fully traceable

State-of-the-Art Manufacturing

Advanced casting workflow plus CNC machining ensures consistent precision for automotive parts.

Rigorous Testing & Inspection

Components undergo CMM, material analysis, and durability testing.

Flexible Capacity & Fast Turnaround

From prototyping to large-scale production under tight automotive timelines.

Customer-Focused Service

Rapid response, transparent communication, tailored support from inquiry to delivery.

QUESTIONS & ANSWERS

Our Client's Frequently Asked Questions

We manufacture turbo housings, engine brackets, structural mounts, heat sinks, and transmission components using investment casting and precision machining.

Yes—we process stainless steel, aluminum, and high-temp alloys with tight tolerances of ±0.01 mm through CNC machining.

Absolutely. All parts go through dimensional inspection, material testing, heat resistance, and mechanical performance checks.

Standard delivery is 4–6 weeks; expedited services are available upon request for urgent production needs.

Yes, we support flexible batch sizes, delivering consistent precision whether it's R&D or mass manufacturing.

Still Have A Questions?

Give us a call at +86-13345064499 or fill out the form below, and our team will be in touch soon