Precision Machining Solutions for the Medical Industry

High-Accuracy, Certified Components for Life-Saving Devices

- Home

- »

- Medical Investment Casting

Medical Investment Casting & Precision Machining

Components for the medical industry have high-dimensional accuracy and require durable and reliable performance.

At Vastcast, we manufacture and supply investment casting products and precision-machined parts for all types of medical devices and equipment.

These parts are used in diagnostic equipment, surgical instruments, and prosthetic and orthopedic implants.

We have established long-term partnerships with hospitals. Thanks to our established one-stop-shop capability, we are able to provide our customers with fast delivery and high-quality products.

We use materials such as 17-4PH, ASTM F-75, and CoCrMo; sizes from 2 mm to 500 mm, and weights from 5 g to 80 kg.

Materials used in medical environments need to meet stringent standards of durability, safety, non-reactivity, and stabilizability for the human body. For example, joint replacements are often made from medical stainless steel or titanium, offering unparalleled strength, flexibility, and functionality.

Materials & Processes

Reliable medical-grade components, tailored with precision.

Materials

🟢 Stainless Steel (316L, 17-4PH)

Corrosion-resistant & biocompatible.

🔵 Titanium Alloys (Ti6Al4V)

Strong, lightweight, highly biocompatible.

🟠 Specialty & High-Temp Alloys

Reliable in demanding medical applications.

Processes

⚙️ Medical Investment Casting

Complex, thin-walled medical components.

🔧 CNC Precision Machining

High accuracy, ±0.01 mm tolerances.

✨ Surface Treatments

Polishing, electro-polishing, coatings.

Applications in the Medical Industry

Delivering Precision Solutions for Critical Healthcare Needs

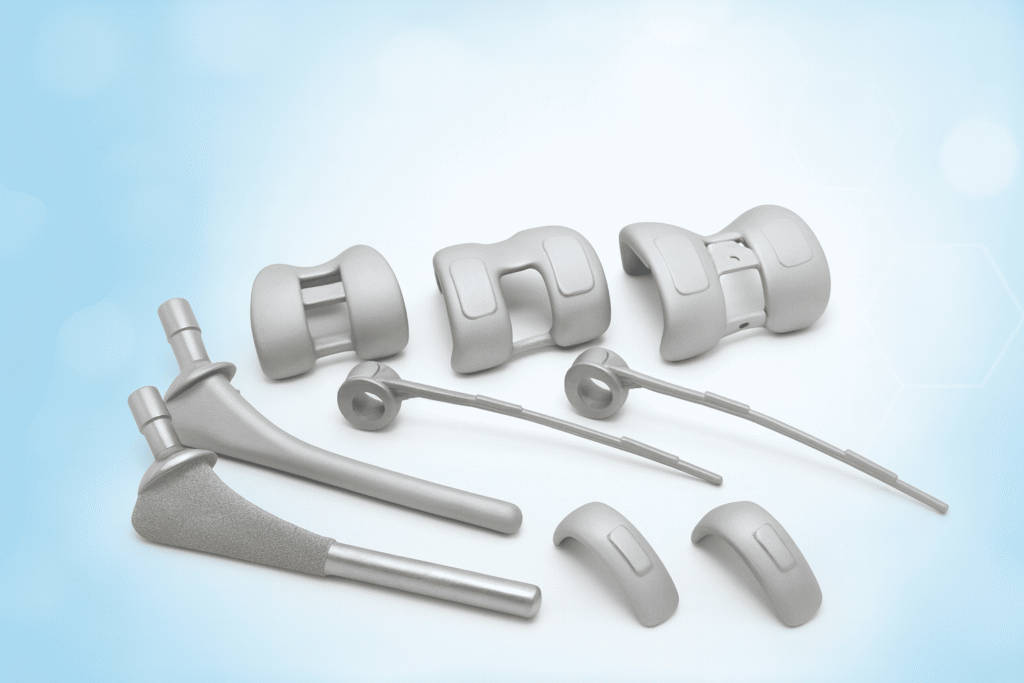

Orthopedic Implants

Hip and knee replacement parts, bone fixation devices designed for strength and biocompatibility.

Surgical Instruments

Forceps, clamps, surgical blades, and other critical surgical tools requiring accuracy and durability.

Dental Components

High-quality implants, orthodontic parts, and accessories for modern dental treatments.

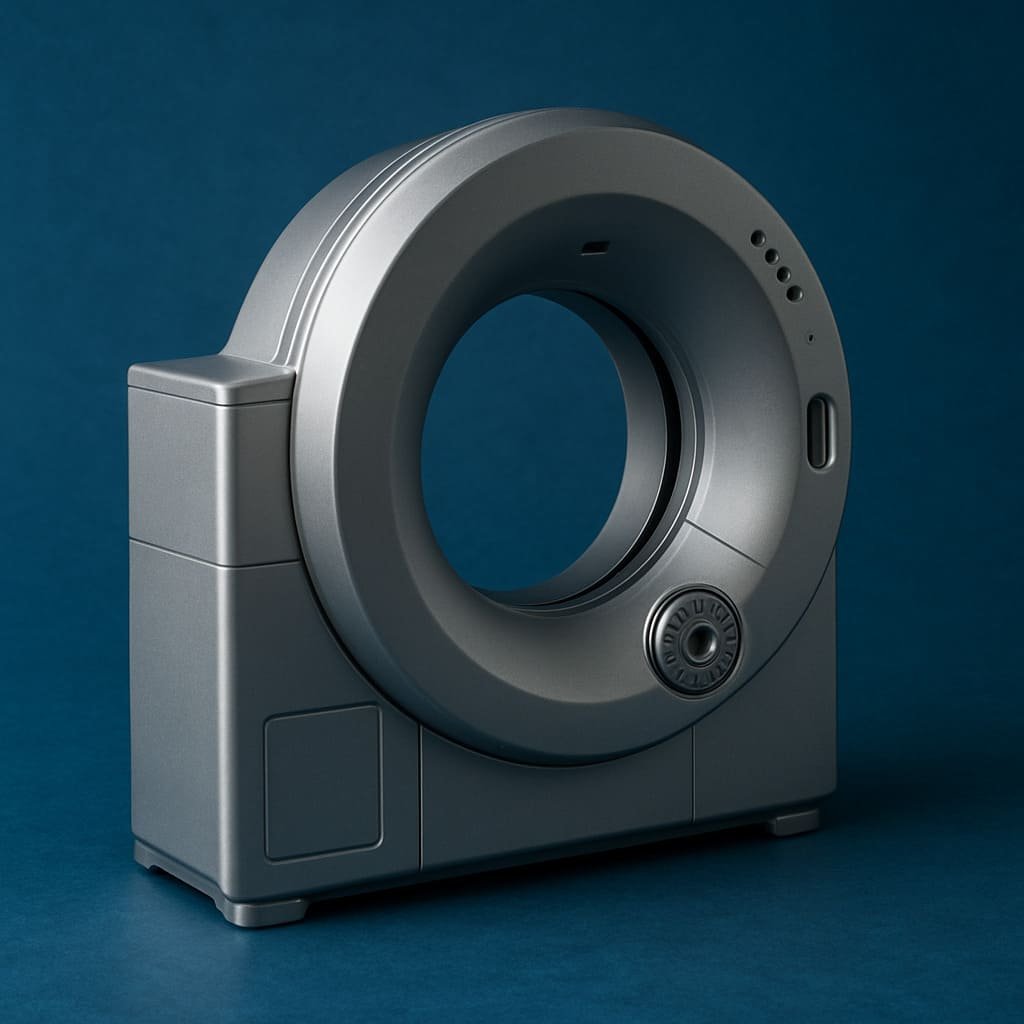

Diagnostic Equipment

Precision components for imaging machines, monitoring systems, and diagnostic devices.

Optional Subtitle

Why Choose Us?

If you are looking for the right medical investment casting manufacturer in China, we are your best choice!

Expert Engineering Team

Our skilled professionals and certified specialists guarantee reliable solutions for critical healthcare applications

Assured Quality

Certified with ISO 9001:2015 and supported by strict testing, every medical component meets international standards with full traceability.

Advanced Manufacturing Technology

From 3D modeling to rapid prototyping and CNC machining, we ensure precision even in the most complex medical parts.

Comprehensive Testing & Inspection

Each product undergoes thorough inspections and performance checks to ensure safety and durability.

Flexible Production Capacity

Whether you need prototypes or large-volume production, we deliver with speed, accuracy, and consistency.

Customer-Centered Service

With fast response times and tailored support, we focus on your needs from inquiry to final delivery.

QUESTIONS & ANSWERS

Our Client's Frequently Asked Questions

We mainly process stainless steel (316L, 17-4PH), titanium alloys (Ti6Al4V), and other high-performance alloys. These materials ensure biocompatibility, corrosion resistance, and long-term durability in medical applications.

Yes. Our facility is ISO 9001:2015 and ISO 14001:2015 certified, and we strictly follow medical-grade quality management. All products undergo full traceability and comprehensive testing before delivery.

Absolutely. We offer flexible production capacity—from rapid prototyping for R&D projects to mass production for established medical devices.

We combine investment casting, CNC precision machining, and advanced inspection methods (CMM, X-ray, and non-destructive testing) to ensure every component meets tight tolerances and performance requirements.

Standard lead time is 3–5 weeks, depending on the complexity and order size. For urgent projects, we also provide fast-track service to support your time-to-market.

Still Have A Questions?

Give us a call at +86-13345064499 or fill out the form below, and our team will be in touch soon